|

|

|

|

|

|

|

||||||||

|

|

|

|

|

||||||||||

|

|

|

||||||||||||

|

Cards -

Coupons - Envelopes - Labels - Leaflets & Paper Feeding |

|||||||||||||

|

Single Feeding, Batch Counting, Single Stream or Twin Stream Models

|

|||||||||||||

|

|

Our Friction Feeders are

designed to feed flat or folded cards, leaflets and magazines, etc. from

credit card size up to an A4 (297 x 210mm) Each item is fed from the bottom of the pile by friction belts. The hopper has an open top and can be continuously replenished whilst running |

|

|

||||||||||

|

|

|||||||||||||

|

|

|

||||||||||||

|

Please click on Next or Back to view the whole site |

|||||||||||||

|

|

Micro-processor control allows for an automatic

self correcting feature to be incorporated. This feature means that when the feeder

comes to a product that is out of place in the stack, where most feeders

would stop, this feeder will continue to feed correctly. Each feeder has a separate electronic control box which can be positioned anywhere within 1.5 meters of the feeder. The power supply requirement is 240v, 1ph, 6amps. |

||||||||||||

|

|

We can feed

·

Credit cards ·

Photographs ·

Paper up A4 ·

Coupons ·

Labels ·

Folded Labels ·

Floppy Discs ·

CD’S ·

Leaflets ·

Booklets ·

Envelopes ·

Greeting cards ·

etc, |

|

|||||||||||

|

|

|

|

|||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

|

Note ! We will

customise any of these units to meet your exact requirements. |

Standard inside = 416mm ( other sizes available on request ) |

|

||||||||||

|

Batch counting This attachment is available for dispensing a number of items together. |

Each item may be fed onto

a conveyer, dropped into a tray, box or carton etc.

The feeder can be signalled from an external

source, a photocell or sensor, to remain in synchronisation with any another

piece of equipment. It feeds on a demand signal, the signal can be made

to dispense one or a predetermined number of items as required. |

|

|||||||||||

|

|

|||||||||||||

|

|

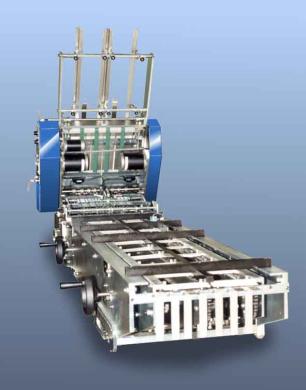

Friction Feeder with lug

conveyor The

unit can be supplied in a twin-single stream version, feeding either two

labels side by side or a single stream down the centre line of the conveyor.

When feeding a twin stream there is a small gap between the labels on the

centreline of the machine. Incorporating a standard Friction Feeder. The

lug conveyer can be changed to (3”, 6”or 9 inch spacings). A quick

change-over method by means of a

selection collar on the side of the machine makes this possible. The whole assembly will slide backwards to accommodate

the longer label lengths. |

|

|||||||||||

|

|

Specification Range of

labels that can be fed. Maximum

300mm wide (across the machine) x 200mm long (single stream) Maximum

150mm wide (across the machine) x 200mm long (double stream) Minimum

38mm wide (across the machine) x

20mm long (double stream) |

|

|||||||||||